Have you ever wondered how these plates transform from a leafy canopy to your dinner table?

These eco-friendly plates, with their natural elegance and sturdiness, have an intriguing backstory. Imagine the journey they take, starting from a simple palm leaf in a tropical forest and ending up as a stylish, sustainable addition to your tableware. The transformation is quite remarkable, involving a mix of traditional methods and modern technology. Curious about how it all happens? Keep reading.

How Palm Plates are made? The Journey of Palm Plates

Collection of Palm Leaves

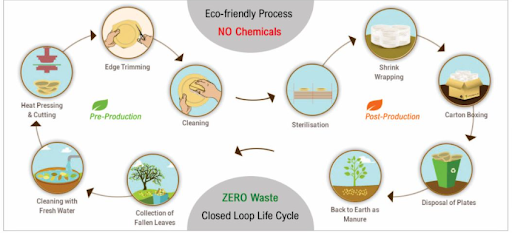

The journey of palm plates begins with the collection of fallen areca palm leaves. These leaves are naturally shed by the areca palm tree, which is commonly found in tropical regions. Unlike other manufacturing processes that require the harvesting of plants, this process uses materials that would otherwise be discarded, making it highly sustainable.

Leaf Washing

The cleaned leaves are then washed with high-pressure water jet sprays to ensure thorough cleanliness. This step is critical in ensuring the finished product meets the highest standards of hygiene.

Leaf Storage

The washed leaves are stored in a clean and dry environment to prevent any contamination or damage. This step is crucial in maintaining the quality of the leaves and ensuring they remain usable for the manufacturing process.

Shaping with Innovation

Skilled engineers have designed state-of-the-art machinery specifically for shaping palm leaves. Using this machinery, the leaves undergo a pressing process, carefully forming them into the various shapes and sizes we see in palm plates. The heat-pressing process not only shapes the leaves but also sterilizes them, making the plates safe for food use. The molds come in various shapes and sizes, allowing for a wide range of products.

A Second Wash and Trimming for Perfection

After the leaves are pressed into plates, they undergo a thorough cleaning process and trimming to remove any excess material or impurities. After trimming, the plates are polished to enhance their appearance and give them a smooth finish. This finishing touch adds to the aesthetic appeal of the palm plates.

Quality Control

Quality control is an essential part of the manufacturing process. Each plate is inspected for defects and imperfections. Plates that do not meet the quality standards are discarded. This rigorous quality control ensures that only the best products reach the market.

Automated Packing

The final step in the journey is packaging. The cleaned and inspected plates are then packed using automated machines that ensure high-quality packing and a PDI check before packing. This step ensures that the plates are safely stored and transported to their final destination.

Finished Goods Storage

The packed carton boxes are stacked on pallets with traceability stickers and shipping marks. This step ensures that the products are safely stored and easily tracked throughout the supply chain.

Palmware's Unique Manufacturing Process

Custom-Built Machines

Palmware is at the forefront of innovation with custom-built machines, designed by an NDA team, ensuring top-quality production. These machines are customized specifically for the efficient and eco-friendly manufacturing of palm plates, setting us apart from other manufacturers.

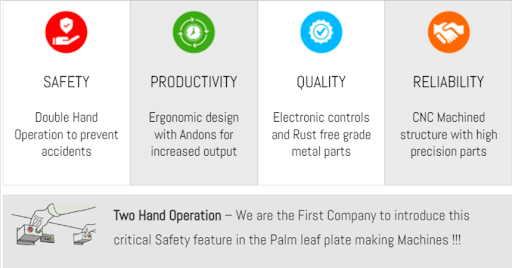

Two-Hand Operation

Palmware also implements a pioneering two-hand operation system, enhancing safety and precision in the production process. This unique approach, combined with their state-of-the-art machinery, highlights Palmware as the first to bring such advanced technology to the palm plate manufacturing industry.

Environmental Benefits of Palm Plates

Biodegradability

One of the most significant benefits of palm plates is their biodegradability. Unlike plastic plates, which can take hundreds of years to decompose, palm plates break down naturally within a few months. This reduces the amount of waste that ends up in landfills and oceans.

Sustainability

The use of naturally fallen leaves makes palm plates a highly sustainable option. It eliminates the need for cutting down trees or using harmful chemicals, reducing the overall environmental impact.

Versatility

Palm plates are not only eco-friendly but also versatile. They can be used for a variety of purposes, from everyday meals to special occasions. Their natural look and sturdy design make them a popular choice for eco-conscious consumers.

Supporting Local Economies

The production of palm plates often takes place in rural areas, providing employment opportunities to local communities. This helps in supporting local economies and promoting sustainable development.

A Plate with a Purpose

The next time you use a palm plate, take a moment to appreciate its remarkable journey. From a fallen leaf in a tropical grove to a sustainable addition to your table, palm plates represent a conscious effort to create a greener future. They offer a beautiful and functional way to enjoy your meals while minimizing environmental impact. So, embrace the story behind these plates and savor a more sustainable future, one plate at a time.

Looking to put the “wow” in eco-friendly? Check out palmware! We are an eco-friendly palm leaf tableware manufacturer that offers a sustainable alternative to traditional disposable tableware. Our manufacturing process is designed to ensure high-quality products with minimal environmental impact. We use a state-of-the-art facility and a skilled team to produce hygienic and beautiful palm leaf dinnerware.

Head to our Manufacturing Process page to see our commitment to ethical production, and browse our Products to find the perfect palm leaf plates for your next gathering! Reach out for orders or more insights into our products.

Hmmm, now you all know that the next plate you use has once swayed in the breeze on a tropical tree, right? Share your thoughts on this in the comments below.