We have a state of art manufacturing facility for producing the hygienic and beautiful palm leaf dinnerware. A well planned process design , a skilled team along with the hi-tech machinery brings the best product out of these natural raw material, gifted by our Mother Earth

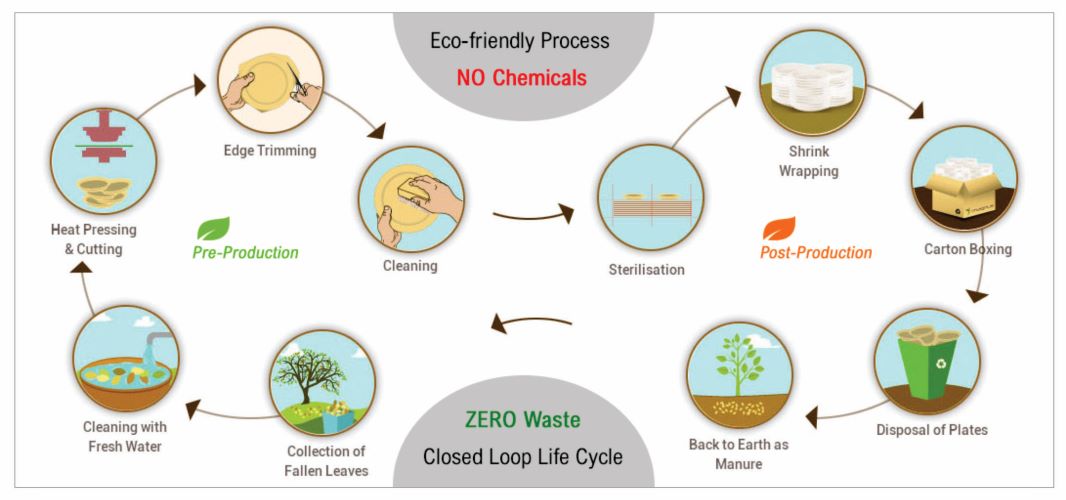

PRODUCT & PROCESS LIFE CYCLE

Palm leaf manufacturing is very cool & simple. Just Wash, & Heat Press.

This cool simple process leads to very less Carbon Footprint when compared to other disposable alternates in the market.

There are no chemicals or additives used in the entire manufacturing process.

Even the water used for cleaning is collected and irrigated for the Green cover in the factory premises with no need of filtration.

When competitors shy away to show their facility, we are proud to share with you.....

Our Manufacturing facility is located in Arasur, Coimbatore with an operational area of around 80,000 square feet

state of art manufacturing

Spacious & Clean Factory

We treat the shop floor as one of the most critical area to be focused in the product manufacturing process. We practice 5’S’ in all the areas. Well maintained layouts with regular cleaning and an any time tidy factory floor is our proof of commitment

Leaf Storage

The hygiene starts from storing of the leaves. We give much importance to the raw material storage thus ensuring good quality leaves throughout the year which in turn significantly enhances the quality level of the finished products and achieving delivery targets

Leaf Washing

Leaf washing is one of the most critical process to ensure cleanliness of the finished product. The leaves are washed with high pressure water jet spray followed by segregation process. It’s one of the notable high differentiation process of Magnus

State of Art Palm Leaf Plate Making Machineries

All the Palm leaf plate Making Machines, Dies / Moulds, Material handling Equipment are designed and developed by our In-house NPD Design & Engineering team.

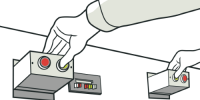

SAFETY

Double Hand Operation to prevent accidents

PRODUCTIVITY

Ergonomic design with Andons for increased output

QUALITY

Electronic controls and Rust free grade metal parts

RELIABILITY

CNC Machined structure with high precision parts

Two Hand Operation – We are the First Company to introduce this critical Safety feature in the Palm leaf plate making Machines !!!

Product Cleaning & Inspection

The cleaning is yet another important process and it is being done by skilled operators in 2 stages. We ensure that every single piece pass through the quality check in order to achieve the quality levels that our customers would love to see.

Automated Packing

The Shrink packing is done after quality inspection and counting process. Automated machine ensures high quality packing and the PDI check is in place prior to packing the products in the carton boxes. Customised packing is also done as required by Customers

Finished Goods Storage

The packed carton boxes are neatly stacked on the pallets with traceability stickers and shipping marks. High quality carton boxes ensure products are safe when stored for longer duration in the warehouse or during the transit to the final destination.